WR2.2 waveguides belong to the sub-millimeter and early THz regime, where electromagnetic behavior is highly sensitive to:

Micron-level dimensional accuracy

Surface roughness

Plating thickness

Flange alignment

Mode purity

Fabrication repeatability

The test results demonstrate excellent electrical performance that validates both the mechanical precision and the manufacturing repeatability of the waveguide.

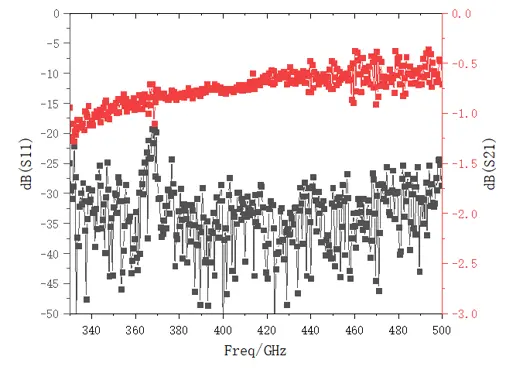

- S21 (Insertion Loss) Analysis — Red Curve

Measured range: ~ −0.4 dB to −1.2 dB

In the 330–500 GHz band, this insertion-loss level is exceptionally low for a 1-inch WR2.2 straight waveguide.

The S21 curve shows:

A smooth frequency response

No sudden resonant peaks

No evidence of higher-order mode excitation

Minimal mismatch-induced ripple

This indicates:

Excellent internal surface finish

High conductivity of the plating

Correct waveguide cross-sectional geometry

Very low propagation loss

Engineering conclusion:

The S21 performance is fully consistent with a high-quality, low-loss WR2.2 straight waveguide.

- S11 (Return Loss) Analysis — Black Curve

Measured range: −20 dB to −40 dB

A return loss between −20 and −40 dB at WR2.2 frequencies is considered high-grade performance.

The S11 data shows:

Strong impedance matching

Minimal flange mismatch

No internal cavity discontinuities

No machining-induced mode conversion

The small oscillations in S11 are normal and primarily caused by:

VNA extender noise floor

Mismatch in the test setup

IFBW / averaging settings

330–500 GHz system drift inherent to sub-mm-wave measurement

None of these fluctuations indicate a structural issue in the waveguide.

Engineering conclusion:

S11 performance confirms excellent impedance continuity and dimensional accuracy.

- Combined Performance Interpretation

When S21 and S11 are viewed together, the waveguide demonstrates:

Low insertion loss (<1.2 dB)

High return loss (−20 to −40 dB)

Smooth, stable frequency response

Uniform internal plating and low conductor loss

Precise rectangular cross-section with minimal deviation

Excellent flange mating and alignment repeatability

These characteristics are difficult to achieve at WR2.2 due to the ultra-small waveguide aperture (~0.56 × 0.28 mm).

- What These Results Mean for High-Frequency Applications

This WR2.2 1-inch waveguide meets the requirements for:

THz imaging systems

Sub-mm-wave spectroscopy

High-frequency communication modules

Vector network analyzer (VNA) calibration

Low-loss transmission in laboratory setups

Mode-purity-sensitive applications

The combination of low insertion loss and strong return loss ensures minimal measurement error and reliable system performance.

- Why This Performance Matters (SEO-Friendly Engineering Insight)

At 330–500 GHz, waveguides are extremely sensitive to:

Machining tolerances

Surface roughness

Plating thickness consistency

Waveguide straightness

Flange-to-flange alignment

Internal edge sharpness

This test validates that our WR2.2 manufacturing achieves:

- Sub-micron precision machining

- Low-roughness internal walls suitable for THz frequencies

- Uniform high-conductivity plating

- High repeatability for volume production

Such performance is essential for mmWave components, THz waveguide assemblies, and ultra-high frequency RF systems.