This modification provides several important manufacturability and performance advantages:

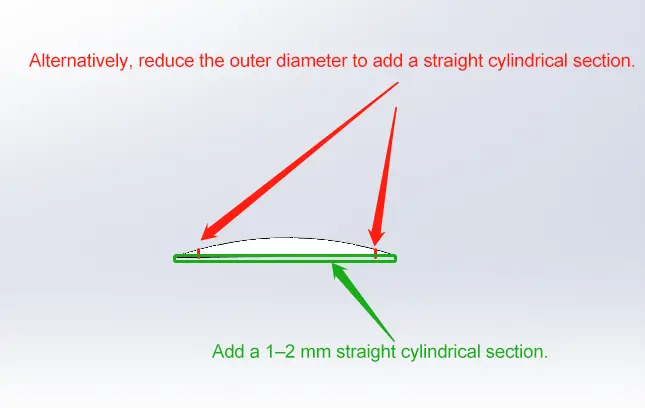

1. Improved fixturing stability by adding a 1–2 mm straight cylindrical base

The original design had the curved lens surface extending directly to the outer edge, making it difficult to align and clamp during machining.

By introducing a small straight cylindrical section:

The part can be reliably located using a 3-jaw chuck, custom fixture, or V-block

Concentricity is easier to control

Cutting forces become more stable, reducing vibration

The curved surface is machined more consistently with minimal runout

Result: higher machining stability and accuracy.

2. Reduced risk of tool interference and improved toolpath control

Slightly reducing the outer diameter creates a safe transition between the curved surface and the clamping diameter.

Benefits include:

A clear and safe entry/exit zone for the cutting tool

Lower chance of tool interference or collisions near the edge

Smoother toolpath programming and more predictable cutter compensation

Cleaner contour with fewer burrs or edge defects

Result: safer machining and cleaner surface quality.

3. Easier inspection with a defined reference surface

Curved surfaces are inherently difficult to measure.

The added straight cylindrical land provides:

A repeatable reference for diameter, roundness, and concentricity

A stable baseline to verify the relative position of the lens profile

More consistent quality control during production

Result: improved inspectability and dimensional consistency.

4. Increased edge strength and reduced risk of chipping

If the curved lens surface extends to the very edge, the rim becomes thin and fragile, leading to:

Deformation during cutting

Edge chipping

Burrs or rolled edges

With a straight cylindrical band:

The edge thickness is increased

The part is more resistant to damage during machining

Handling and assembly become safer and more reliable

Result: higher robustness and fewer defects.

5. No impact on optical / RF performance

The modifications only affect the outer mechanical boundary, not the functional lens profile.

The central curved region—which determines optical or mmWave/THz behavior—remains unchanged.

Result: improved manufacturability without compromising performance.

Summary

The updated lens geometry provides:

Better clamping stability

Safer and cleaner machining

More reliable inspection

Higher structural strength

Increased yield and lower production risk

No functional performance impact

This is a textbook example of DFM (Design for Manufacturability):

a small structural adjustment that significantly enhances machining feasibility while keeping optical/RF performance intact.