When Surface Smoothness Determines the Success of Astronomical Experiments

Astronomical observatories do not need a “mirror.”

They need a flawless optical surface.

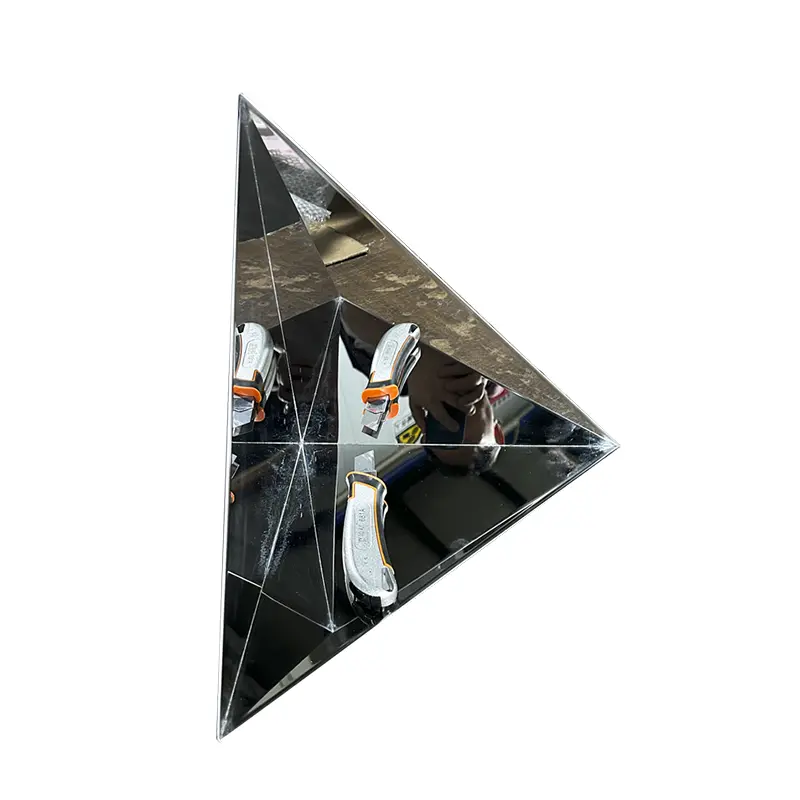

For this project, the research team required a multi-facet reflective structure used for optical path calibration. Each reflective surface had to achieve:

Optical-grade smoothness

No scratches, no haze, no waviness

No micro-pitting or secondary machining textures

Distortion-free imaging even after multiple reflections

In astronomical verification experiments,every trace of scattered light, every minor surface defect, becomes amplified—eventually altering the final measurement results.

The real challenge in astronomical optical structures is not

“Can it be machined?” but “Can it be machined to the cleanliness, purity, and smoothness of an optical component?”

THZ Precision focused on solving three core challenges that typical machining factories cannot handle:

1. Achieving Surface Roughness Comparable to Optical Components, Not Metal Parts

Most metal parts stop at a typical mechanical finish:

Tool marks

Directional texture

Subtle surface waviness

But this project required:

An optical-grade Ra surface finish

Two to three levels above what wire-EDM can achieve

Meaning:

No visible tool marks

No diffuse reflections under direct lighting

A mirror surface that appears bright, clean, and optically deep

No micro-waviness under angled inspection

No scattered light contaminating the reflection image

This level of smoothness is far beyond what standard CNC or wire-EDM can achieve.

It requires:

Multi-stage precision polishing

Cross-surface uniformity control

Residual stress relief

Optical-surface finishing techniques

These capabilities are exactly what THZ Precision has refined through years of manufacturing THz cavities, waveguide apertures, and horn reflector surfaces.

2. Optical-Grade Surfaces Combined with Multi-Facet Angular Consistency — Difficulty Multiplied

As surface smoothness requirements increase, the tolerance for structural deformation decreases.

This component is a trihedral configuration, which adds complexity:

All mirrors must converge perfectly at a geometric center

No micro-warping, no lifted edges

Any localized stress immediately causes “breaks” in the reflected image

Producing optical-grade surfaces is already difficult.

This structure further requires:

Optical surface quality + precision angular geometry + zero-distortion multi-reflection performance

This combination eliminates the majority of conventional machining suppliers.

3. Clear, Distortion-Free Multi-Reflection Imaging — The Final Test of Surface Quality

During inspection, the client placed a simple utility knife inside the chamber.

The photograph they captured became the most direct proof of surface quality:

Razor-sharp mirror edges with no trailing

No halos caused by scattered light

No curvature or distortion from surface waviness

True-to-size reflections even after multiple bounces

In other words:

The mirrors are not only flat, but clean.

Not only smooth, but stable.

Not only reflective, but precise.

Why Surface Smoothness Matters: It Determines Signal Purity

Astronomy deals with extremely weak signals.

A slight increase in surface roughness can amplify noise ten-fold or a hundred-fold.

This type of optical structure is used for:

Star sensor calibration

Optical path consistency verification

Laser alignment systems

Terahertz experimental setups

Multi-angle reflection path testing

All these applications require one thing in common:

The reflected signal must remain pure.

And purity begins with the mirror surface.

Precision Defines Geometry. Smoothness Defines Quality.

In this project, THZ Precision did not simply deliver a “mirror structure.”

We delivered:

Optical-grade reflective surfaces

Multi-facet geometry with zero distortion

Experiment-verified stable imaging performance

A component that meets true optical-instrument quality standards

We are not making metal parts.

We are manufacturing optical structures for scientific experimentation.