In the millimeter-wave and sub-THz world, most machining vendors cannot achieve true R = 0 corners at waveguide apertures—let alone surface quality surpassing slow-wire EDM.

This challenge has remained unresolved at scale for decades because it lies at the intersection of mechanical geometry, material behavior, stress control, and electromagnetic performance.

Why Typical Machine Shops Cannot Achieve R = 0

1. Tool tips have intrinsic radius—physically impossible to be zero

Micro end mills inherently have a minimum tool-tip radius.

Typical values in conventional shops: 0.04–0.15 mm,

which makes mathematical sharp corners physically unachievable.

2. High local stress causes chipping, rounding, and burrs

At internal corners, toolpaths induce instant lateral force peaks.

Standard machines and fixtures cannot maintain tool stability, resulting in:

Corner rounding (increased R)

Burr formation

Wall thickness inconsistency

RF performance degradation

3.Why Slow-Wire EDM Still Fails for High-Frequency Requirements

Many engineers assume:

“Just use wire EDM—EDM gives a perfect sharp corner.”

But in high-frequency structures, EDM’s advantages turn into critical drawbacks.

1. EDM achieves geometric corners, but not RF-grade surface finish

Typical slow-wire EDM surface roughness:

Ra = 0.8–1.2 μm (fine settings)

However, high-frequency fields are extremely sensitive to metal wall roughness.

EDM textures introduce loss, scattering, and mode impurity.

2. EDM creates a heat-affected (recast) layer

Electrical discharge inherently forms:

Recast layer

Micro-pitting

Altered surface metallurgy

These are unacceptable in mmWave/THz waveguides.

What we need is RF-level corners, not machining-level corners.

THZ Precision’s Solution: Making R = 0 a Repeatable, Scalable, Performance-Critical Capability

We do not “force” tool radius to zero.

Instead, we apply a complete RF-aware manufacturing system to create effective sharp corners with superior surface integrity.

Step 1 — RF-Aware Geometry Prioritization

Before machining begins, we evaluate:

Which channels are most mode-sensitive

Which corners require true geometric R = 0

Where 0.005–0.01 mm tolerance is acceptable without EM degradation

Local field-boundary coupling behavior

While standard machine shops see geometry,

we analyze the electromagnetic consequences behind the geometry.

Step 2 — Custom Micro-Tooling for Sharp-Corner Formation

We use non-standard micro-tools:

Ø0.1–0.2 mm micro end mills

Custom tool-tip angle

Ultra-short helix geometry

Specialized coatings

Near-zero effective tool-tip radius

Combined with toolpath strategies that avoid lateral shock loading, ensuring no chipping, no secondary rounding, no tool vibration.

Sharp corners are designed, not “cut by luck.”

Step 3 — Layered Micro-Milling

Conventional machining uses “one-pass” cutting.

We use multi-stage removal:

Rough → Semi-finish → Finish → Super-finish

Material removal per pass: 5–10 μm

Stress-minimized toolpath planning

This yields stable, controlled edges:

no deformation, no collapse, no rounding.

Step 4 — High-Frequency Surface Conditioning

To surpass EDM-quality by 2–3 grades, we apply:

Ultra-fine corner clearing

Deburring without geometric modification

Micro-scale edge tuning

Local field-current path smoothing

Final Results (Verifiable, Repeatable, and Scalable)

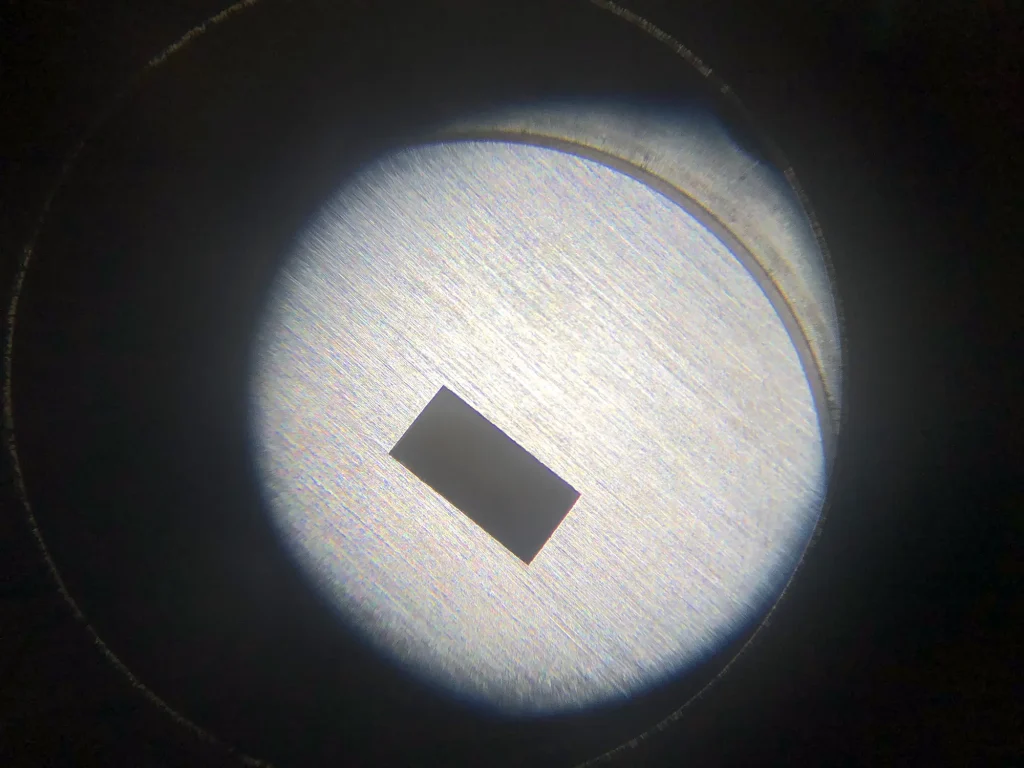

1. True Sharp Corners (R = 0)

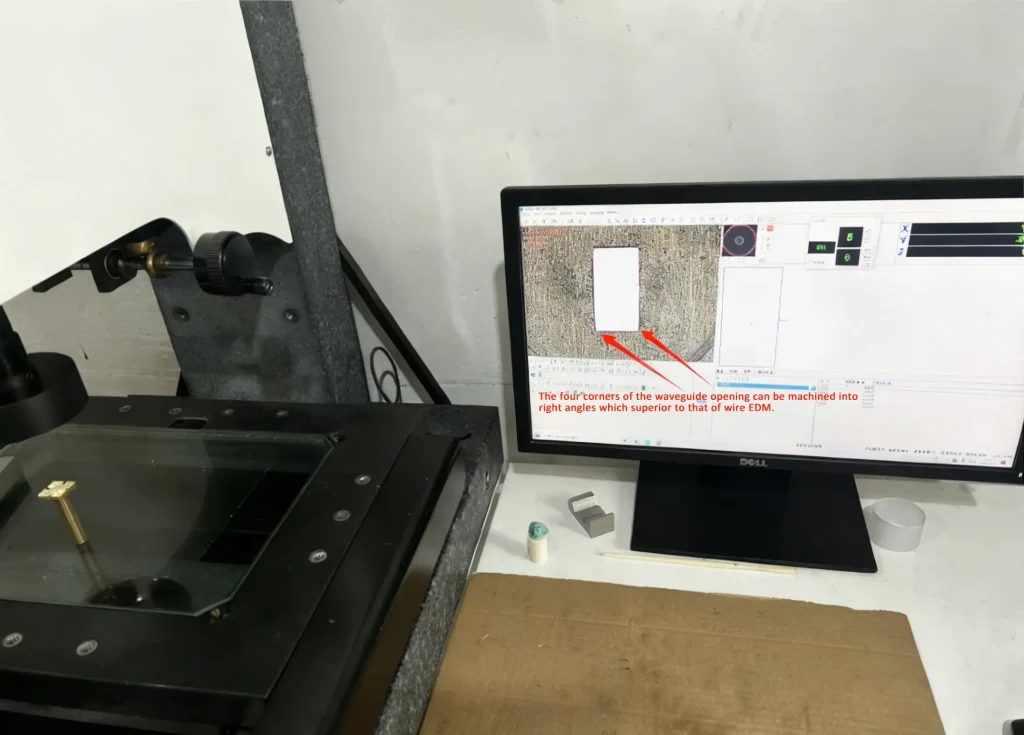

Under 50–200× microscopy:

Clean and sharp edges

No measurable rounding

No chipping

No edge collapse

2.Surface Integrity Superior to Slow-Wire EDM

Ra = 0.1–0.2 μm

High surface uniformity

Reduced high-frequency loss

Improved current distribution

3.Stable RF Test Performance

S11 smoother

Lower ripple and sidelobes

Better batch-to-batch consistency

Reduced measurement variation

Why This Capability Is Unique to THZ Precision

Because we are not a machining vendor.

We are a manufacturer who understands high-frequency structures.

Our process ensures:

Geometric accuracy → Stress accuracy → Assembly accuracy → RF accuracy → Batch consistency

This transforms high-frequency structures into:

manufacturable, testable, and scalable products.

R = 0 is not a machining action.

It is a manufacturing philosophy for high-frequency engineering.

It demands an integrated understanding of:

Electromagnetic fields

Material stress

Tool dynamicsR = 0 is not a machining action.

It is a manufacturing philosophy for high-frequency engineering.

It demands an integrated understanding of:

Electromagnetic fields

Material stress

Tool dynamics

Surface integrity

Assembly behavior

This is the fundamental difference between THZ Precision and standard machining shops.

And this is why we consistently achieve:

Sharper corners, cleaner surfaces, and more stable RF performance—far beyond what slow-wire EDM can offer.