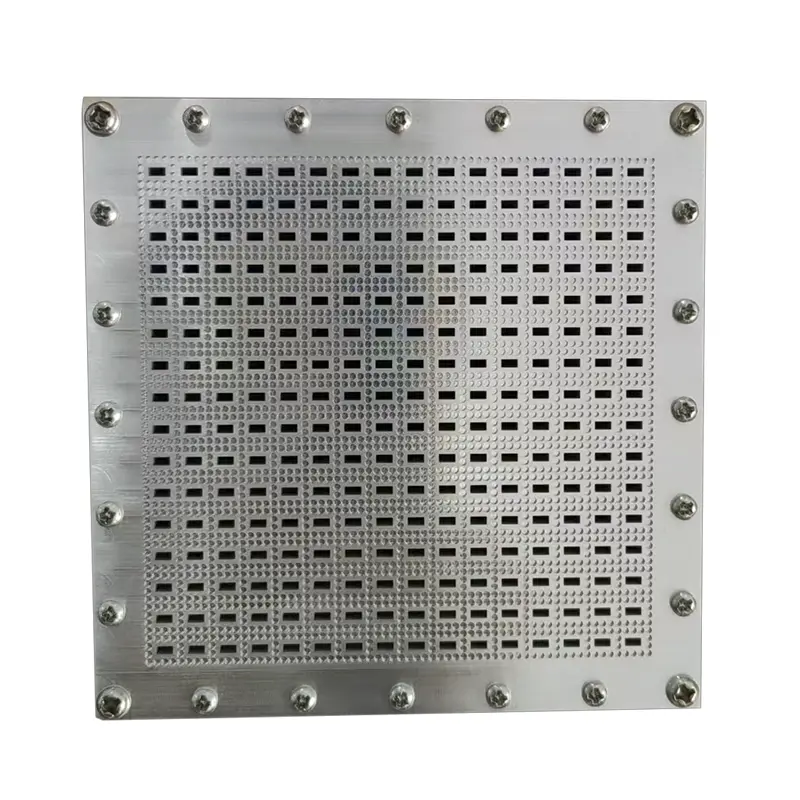

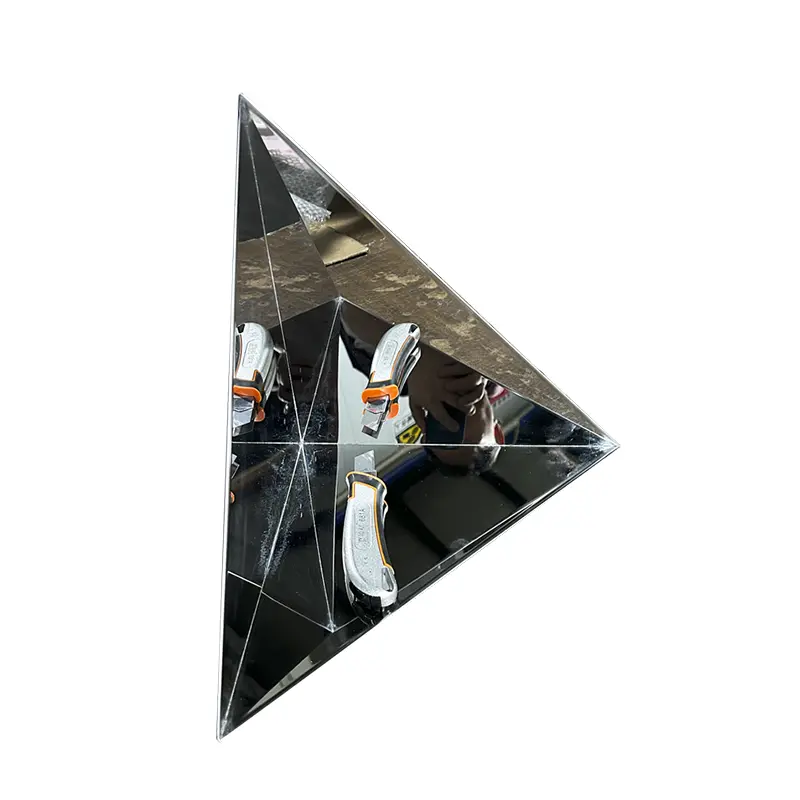

Precision Machining for Millimeter-Wave RF Modules

We provide high-precision machining and integration services for millimeter-wave RF modules, supporting complex waveguide structures, tight tolerance interfaces, and stable RF performance across mmWave and THz frequencies. Our capability bridges discrete components and functional RF assemblies.

Engineering Capabilities

Ultra-tight tolerance control for mmWave critical dimensions.

Precise alignment of split-block and mating interfaces.

Waveguide-aware machining with understanding of RF-critical geometries.

Stable surface quality to ensure low loss and repeatable RF performance.

Complex internal cavities and waveguide features via CNC and EDM .

Typical RF Module Housings & Tooling

Passive RF module housings (power dividers, filters, couplers).

Active RF module housings (mixers, amplifiers, multipliers).

Frequency control modules (synthesizers, phase shifters, attenuators).

Precision corner reflector and calibration structures.

Custom waveguide fixtures, alignment and test tooling.

Capability Snapshot

Min tolerance: ±0.003mm.

Minimum milling tool size: φ0.06 mm.

Surface roughness: Ra 0.3 – Ra 0.8.

Materials: Aluminum, Copper, Brass, Stainless Steel (customized).

Surface finishes: Gold plating, silver plating, custom finishes

Note: The images are provided solely to demonstrate machining capability and are not for commercial sale. All customer designs are strictly confidential.

Design for Manufacturability (DFM) Support

Our DFM support focuses on machining feasibility and practical optimization for RF modules.

We analyze design details from a manufacturing perspective—including waveguide geometry, split-block structures, wall thickness, tolerances, and assembly interfaces—to ensure the design can be machined reliably and repeatedly.

Based on this analysis, we provide engineering-level suggestions on how to adjust structures to:

Improve RF performance by maintaining stable waveguide paths and alignment accuracy;

Enhance mechanical strength and long-term stability;

Reduce machining complexity and overall production cost.

By aligning design intent with real machining constraints, we help bridge the gap between prototype and scalable production, enabling smoother transition from one-off samples to stable batch manufacturing.

Confidentiality Assurance

All DFM reviews and technical discussions are handled under strict confidentiality.

Customer drawings, design details, and any optimization suggestions are used solely for feasibility analysis and manufacturing evaluation, and are never shared with third parties or reused for other projects.

Confidentiality is treated as a fundamental requirement, not a formality.